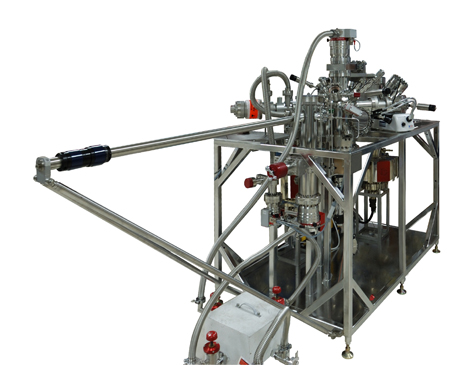

Typical PLD System Configuration and Variations

1. Typical PLD Configuration

The substrate and target are introduced through a load lock chamber opposite the target gearbox. The substrate is then rotated on its polar axis to face the target gearbox. The substrate can be moved out of the way for transfer of the targets. This is one of the most common and economical configurations.

Typical PLD configuration, vertically-mounted substrate manipulator

Typical PLD substrate manipulator with 2" quartz lamp heater

Typical PLD target manipulator, horizontal mount, STLC target system

2. Vertical PLD Configuration

This design features up-facing, gravity-held target holders to accommodate liquid, powder, or conventional targets. A custom transfer fork moves substrates and targets into place via standard load lock chamber.

3. Simple PLD Configuration

This design offers basic substrate and target devices with no XY or Z adjustment. Substrate and target changes are done at atmosphere.

4. Multi-Purpose PLD Configuration

This design permits MBE growth, via bottom-flange-mounted evaporation sources, as well as PLD growth. Substrate assembly faces the side of the chamber for PLD, the bottom for MBE, and the other side for in-vacuum transfer of substrates.

PLD Components

PLD substrate manipulator with 2" quartz lamp heater and gas shower ring.

We offers an extensive line of substrate and target manipulators as well as load lock and sample transfer systems for PLD systems. Our standard modular components can be configured in a variety of ways to meet your specific PLD system design. We can also design, integrate and certify complete PLD systems.

Typical Manipulator Specifications

|

Orientation |

Vertical or Horizontal |

|

X-Y movement |

±0.5" or ±1.0" |

|

Substrate sample |

size<2" diameter |

|

Targets |

6 - 1" (other configurations available) |

|

Sample orientation |

any |

|

Sample heating |

SHQ to 1292°F (water-cooled heater) |

|

Vacuum environment |

UHV, O2 |

|

In-vacuum sample transfer |

optional |

|

Base flange |

8" |