-

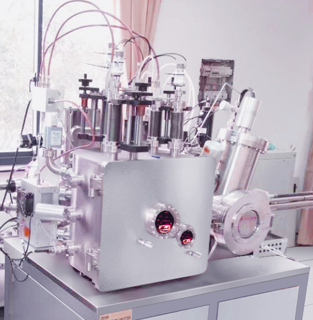

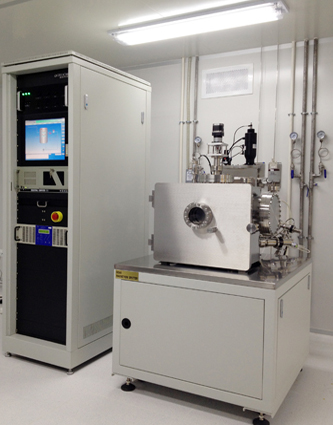

DE500 Magnetron Sputtering System

DE500 Magnetron Sputter are assembled with four sputter sources for sputtering metals, semiconductor and insulation materials on the substrate up to 6” diameter, the sputter chamber base vacuum pressure is 5E-8 Torr, it can be used to sputter alloy film or multi layer film, especially it can be used to sputter very thin film for some typical materials base on the very low sputter pressure, this is the ideal tools for thin film R&D for the university and academy.

Good Film Uniformity and repeatability

Safety interlock for critical components

Advantage:

Vacuum Pressure ≤ 5.0×10-8Torr

Reach 1E-6 Torr<15 mins, reach 5E-7Torr <30mins

Vacuum pressure is 7.5E-2Torr after 100hours from system stop

Working pressure stable: 0.25%Plasma stable at less 1mTorr Batch film uniformity: +/-5%

Substrate heating to 1832°F

Excellent film adhesion